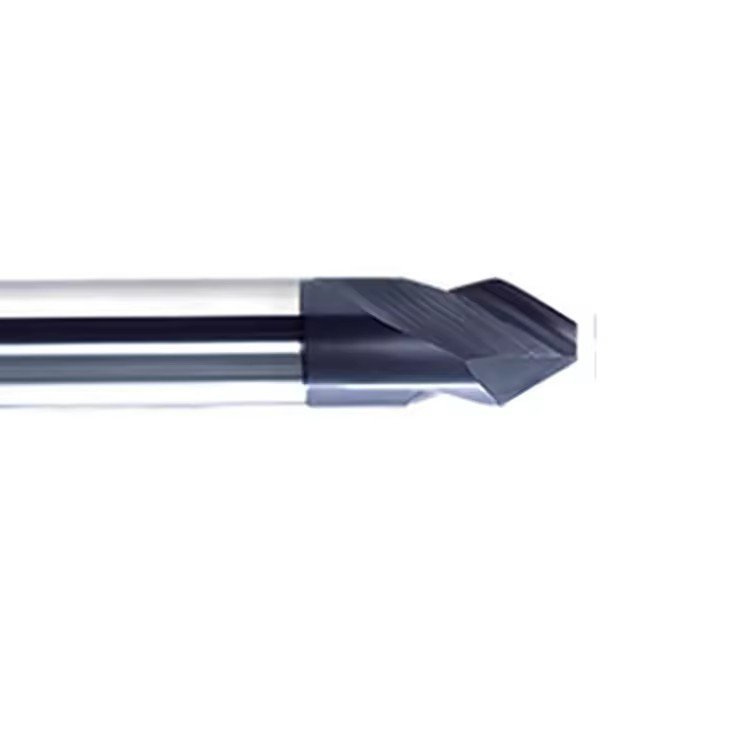

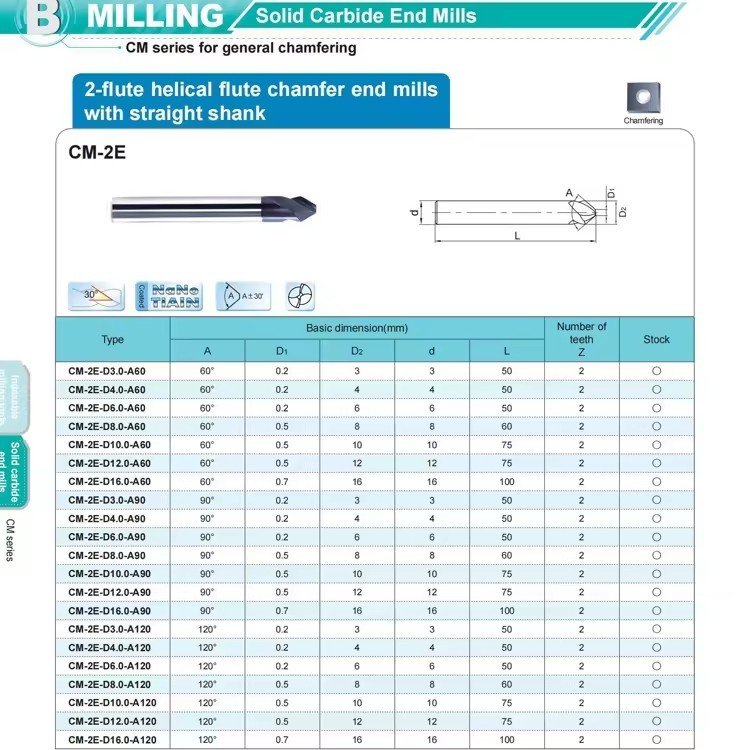

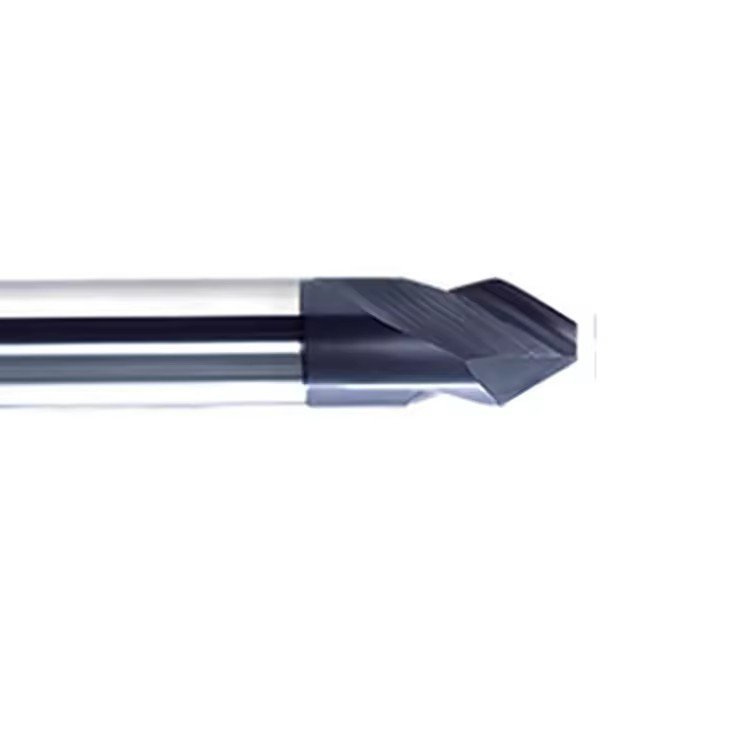

Carbide Chamfer End Mill – High-Precision Tool for Clean Edge Finishing

This carbide chamfer end mill is engineered for precise edge preparation and stable cutting control. It is manufactured from premium micro-grain carbide, ensuring excellent hardness and long tool life. The refined geometry delivers sharp cutting action and reduces burrs on sensitive surfaces. This tool provides consistent performance in demanding production environments. The carbide chamfer end mill enhances stability and supports accurate machining results.

The cutting edges are polished to reduce friction and maintain cooler cutting temperatures. This improves tool life and ensures smoother surface finishes. The rigid structure prevents vibration during high-speed operations. It supports clean chamfering at fixed angles and maintains reliable dimensional accuracy. The design helps users achieve repeatable results across various machining tasks. It performs well on steel, stainless steel, alloy materials, and non-ferrous metals. Designed for precision chamfering, deburring, and countersinking, it meets the needs of professionals who require accurate finishing.

This tool fits CNC machining centers, automated lines, and precision workshop setups. It offers excellent control during edge breaking, surface preparation, and hole entry operations. The sharp point design supports smooth initial contact and reduces tool deflection. Its reliable stability helps maintain consistent chamfer dimensions in long production runs. Coolant or dry cutting conditions are both supported with dependable performance. The carbide chamfer end mill excels when users demand clean edges and high repeatability.

Each tool is inspected to guarantee strict dimensional consistency. The polished shank ensures strong grip and reduces slippage in high-speed rotation. This cutter is suitable for aerospace parts, automotive components, molds, electronic housings, and precision metalwork. It maintains edge quality even under heavy loads or continuous cutting cycles. The optimized flute design also assists chip evacuation and prevents material buildup near the tip.

With its advanced carbide material and refined geometry, this chamfer end mill provides reliable productivity for long-term use. It helps reduce downtime caused by frequent tool changes. Users can expect predictable results across a wide range of metals and machining strategies. The carbide chamfer end mill supports efficient, accurate, and stable finishing in professional manufacturing environments.