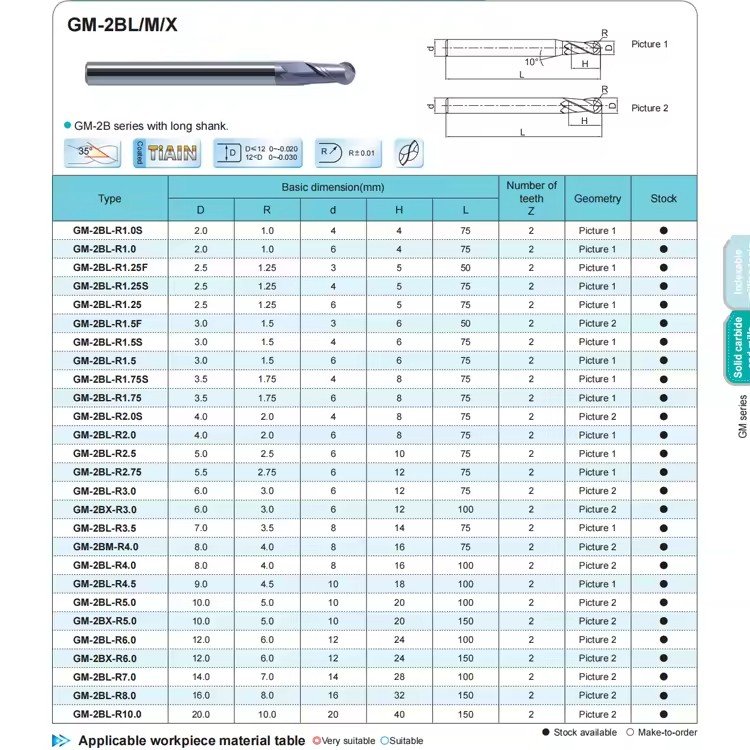

The GM-2BL series solid carbide end mills are designed for precision machining with a long shank for enhanced flexibility in various milling applications. These high-performance tools feature a robust carbide construction, offering excellent durability and wear resistance. The GM-2BL series is ideal for machining a wide range of materials, delivering superior cutting performance and extended tool life.

These end mills are available in various sizes, ranging from 2.0mm to 20.0mm in diameter, providing flexibility for a wide variety of applications. The tools come with multiple radius options (R1.0 to R10.0) to meet the specific requirements of your machining projects. Whether you are working with hard metals or softer materials, the GM-2BL series provides precise and smooth cutting, improving productivity and ensuring excellent surface finishes.

The GM-2BL series tools are specifically designed with advanced geometry for high-efficiency milling, making them suitable for high-speed operations and demanding applications. These end mills feature a well-balanced design, ensuring stability during cutting, which reduces vibration and improves the overall quality of the machined part.

Made from premium solid carbide material, these tools offer exceptional cutting performance, even under challenging conditions. The GM-2BL series is available in both stock and make-to-order options, ensuring quick availability for your production needs. With a range of cutting edge configurations, these tools are perfect for a variety of milling operations, including contour milling, slotting, and profiling.

Features:

Premium solid carbide construction for superior durability

Long shank design for added flexibility in machining

Available in a range of sizes (2.0mm to 20.0mm) and radius options

High-efficiency geometry for improved cutting performance

Ideal for high-speed milling and precision machining

Stock and make-to-order options available

Upgrade your machining process with the GM-2BL series solid carbide end mills. Offering outstanding performance, durability, and precision, these tools ensure high-quality results across a broad range of applications.