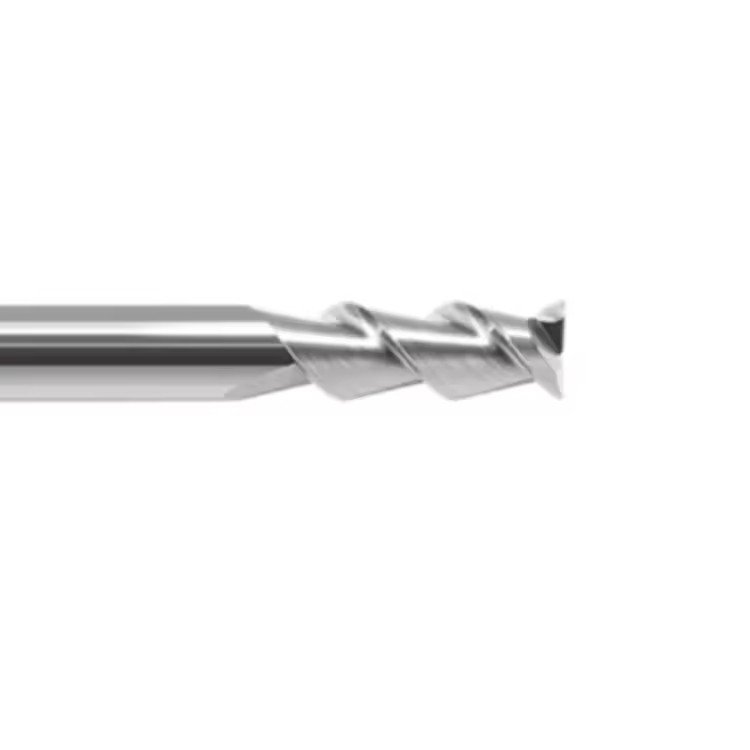

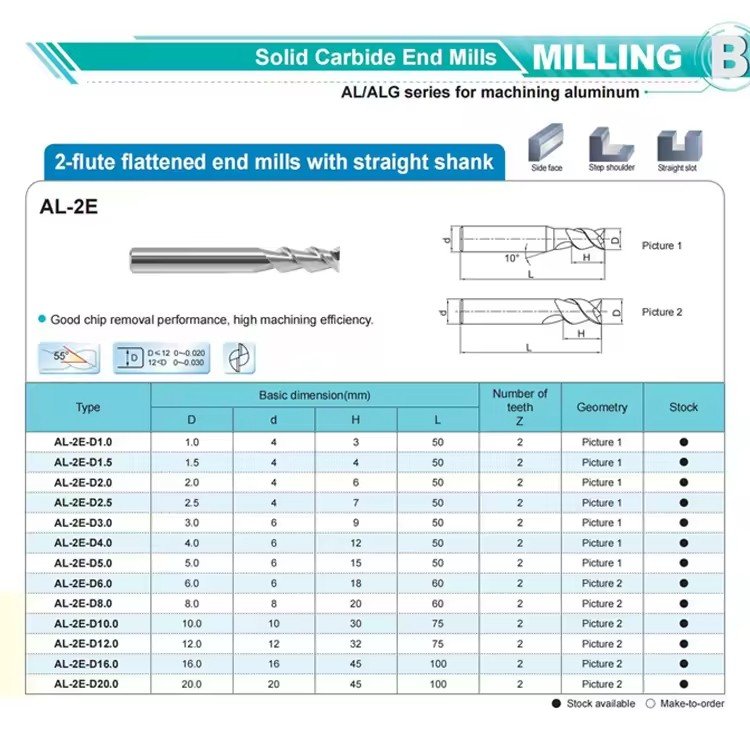

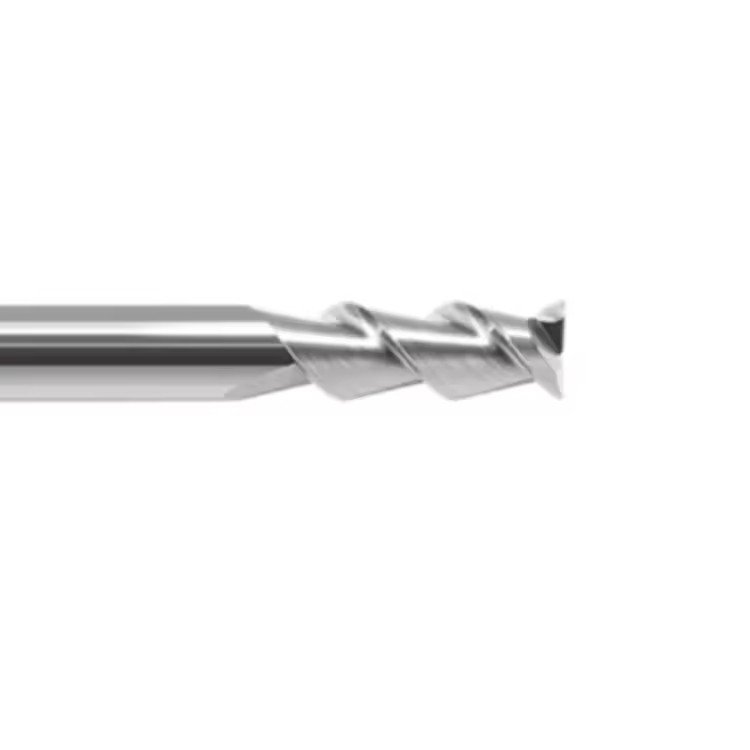

The AL-2E series solid carbide end mills are engineered for high-efficiency milling, specifically designed for machining aluminum alloys. These 2-flute flattened end mills with a straight shank deliver excellent chip removal performance, making them ideal for both high-speed machining and precise aluminum cutting operations.

With a cutting edge geometry optimized for aluminum, these end mills provide superior material removal rates while ensuring smooth finishes. The AL-2E series features various diameters ranging from 1.0mm to 20.0mm, allowing flexibility to meet a wide range of machining needs. The design of these tools enables efficient chip clearance, reducing the chances of material buildup and increasing overall productivity.

Made from premium solid carbide, the AL-2E end mills are durable and resistant to wear, offering exceptional tool life even under heavy cutting conditions. Whether you’re working with softer or harder aluminum alloys, these tools provide consistent performance, reducing downtime and enhancing machining efficiency.

These end mills come in different lengths and configurations to suit various milling tasks, including side-facing, step-shoulder, and straight-slot applications. The AL-2E series ensures precision and high-speed performance, making it an excellent choice for modern manufacturing environments.

Features:

High-efficiency design for aluminum alloy machining

Premium solid carbide construction for durability and wear resistance

Excellent chip removal performance and high material removal rates

Available in a variety of diameters (1.0mm to 20.0mm)

Versatile for different milling operations: side face, step shoulder, straight slot

Long-lasting tool life, minimizing downtime and tool replacement

Upgrade your machining process with the AL-2E series solid carbide end mills, designed to provide high-speed, efficient cutting for a range of aluminum milling applications. Achieve consistent, high-quality results with minimal effort and tool wear.