The 2-flute ball nose end mills are designed for precision milling and contouring applications. Made from high-quality tungsten carbide, these end mills offer superior durability and resistance to wear, making them ideal for machining a wide range of materials, including metals, plastics, and composites.

These tools are perfect for precision cutting tasks such as mold making, 3D profiling, and other contouring operations. The ball nose design allows for smooth, rounded cuts and superior surface finishes. The 2-flute configuration ensures efficient chip removal and stable cutting performance, even at high speeds.

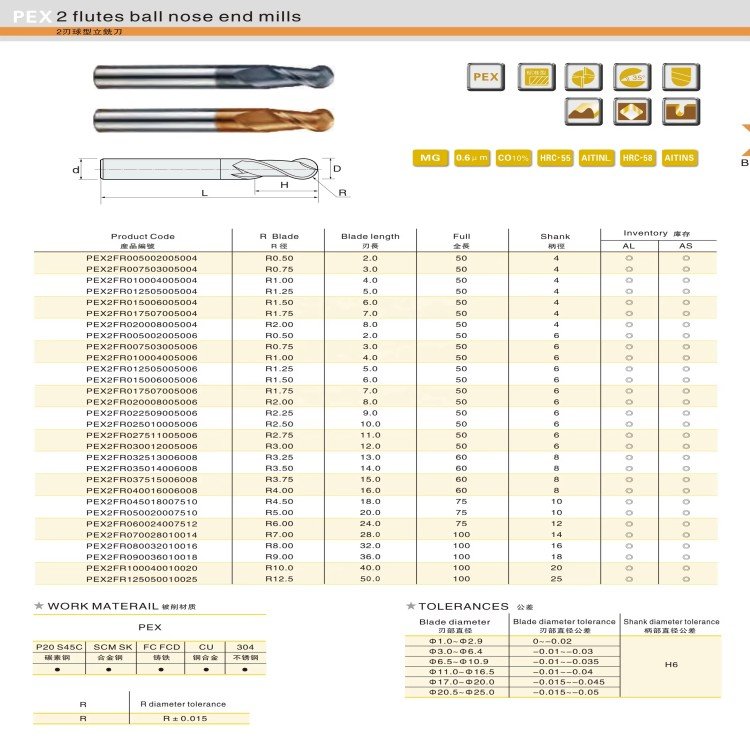

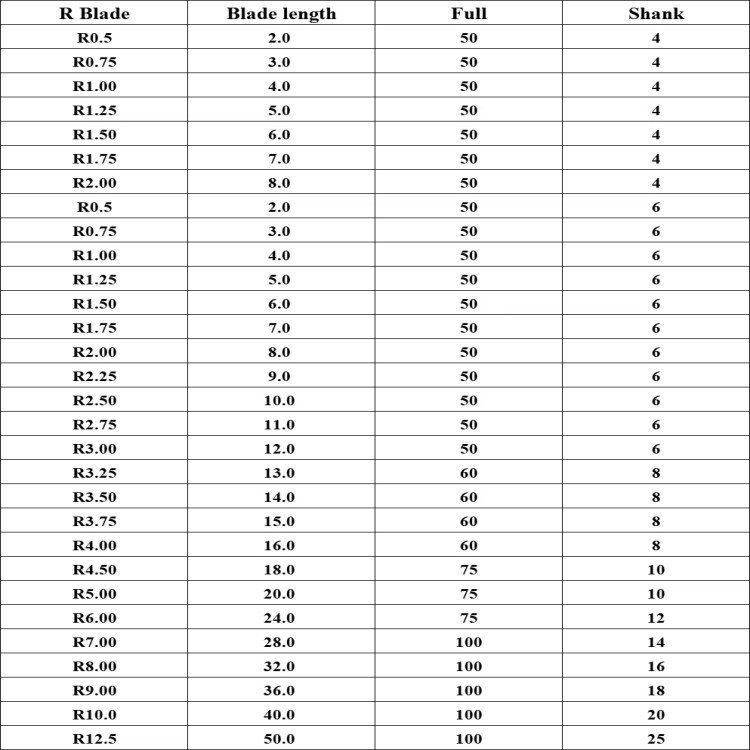

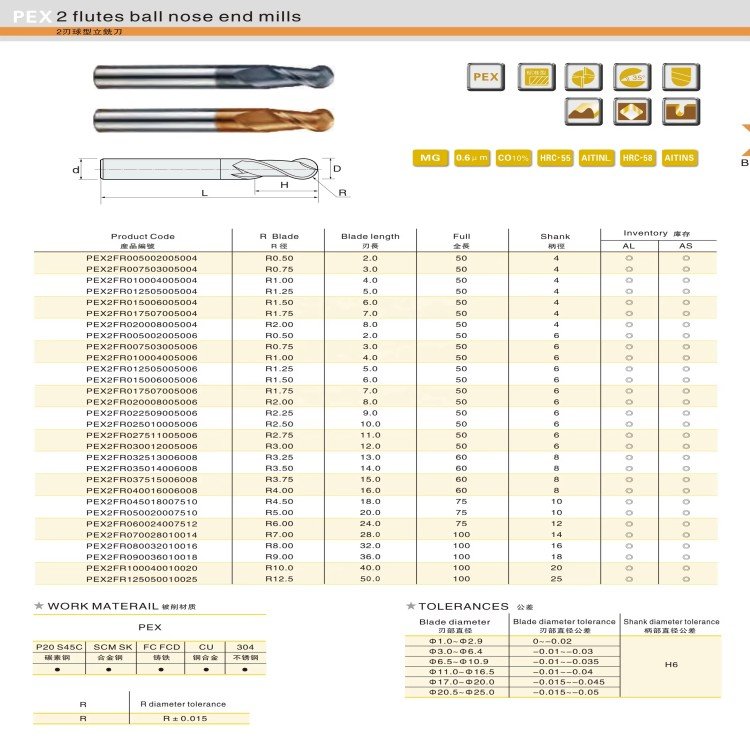

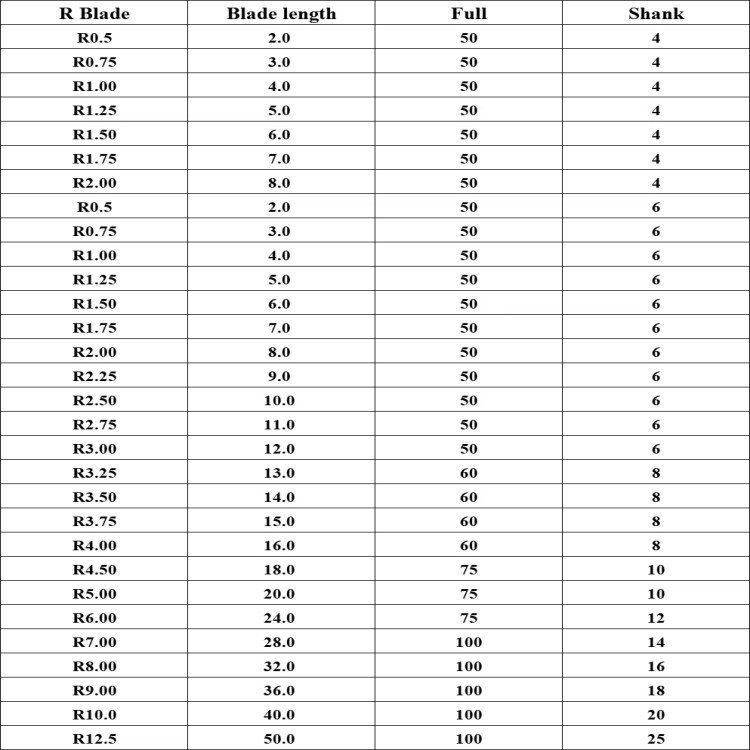

Available in a wide range of radii (R0.5 to R12.5), these ball nose end mills cater to various machining needs, from fine, detailed cuts to larger, more aggressive milling tasks. The high-performance coating enhances the tool’s wear resistance, extends tool life, and ensures consistent results during high-speed machining.

These end mills are ideal for high-precision operations, ensuring clean cuts and excellent surface finishes in both roughing and finishing applications. Whether you’re working with tough alloys or soft plastics, these carbide ball nose end mills provide excellent performance and versatility.

Key Features:

2-flute design for smooth cutting and efficient chip removal

Made from high-quality tungsten carbide for durability and precision

Ball nose design ideal for contouring, profiling, and mold making

Available in radii from R0.5 to R12.5 for versatile applications

Coated with advanced materials for enhanced wear resistance

Perfect for high-speed, high-precision cutting in various materials

Upgrade your machining capabilities with these 2-flute ball nose end mills. Designed for precision and performance, these tools are perfect for a variety of complex milling applications, offering consistent results and long-lasting durability.