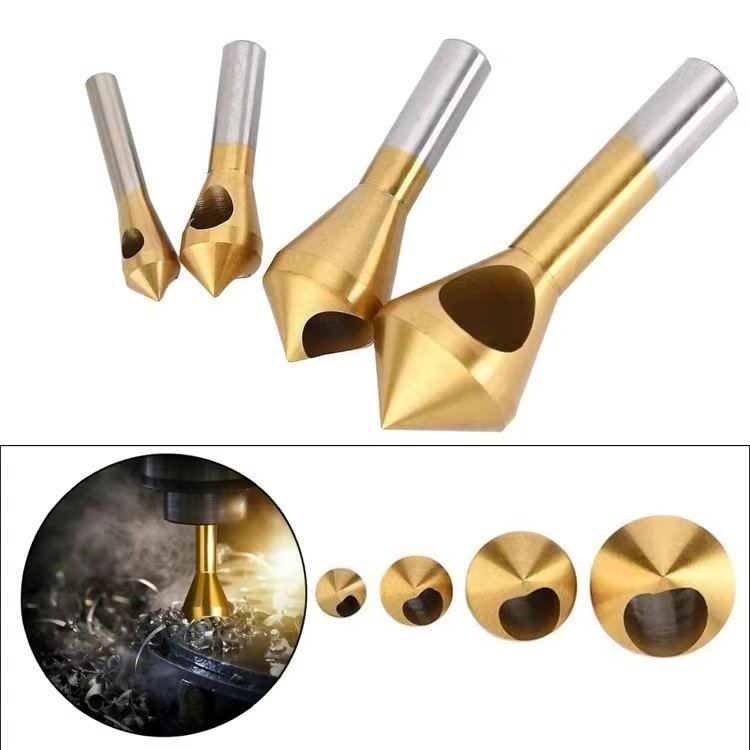

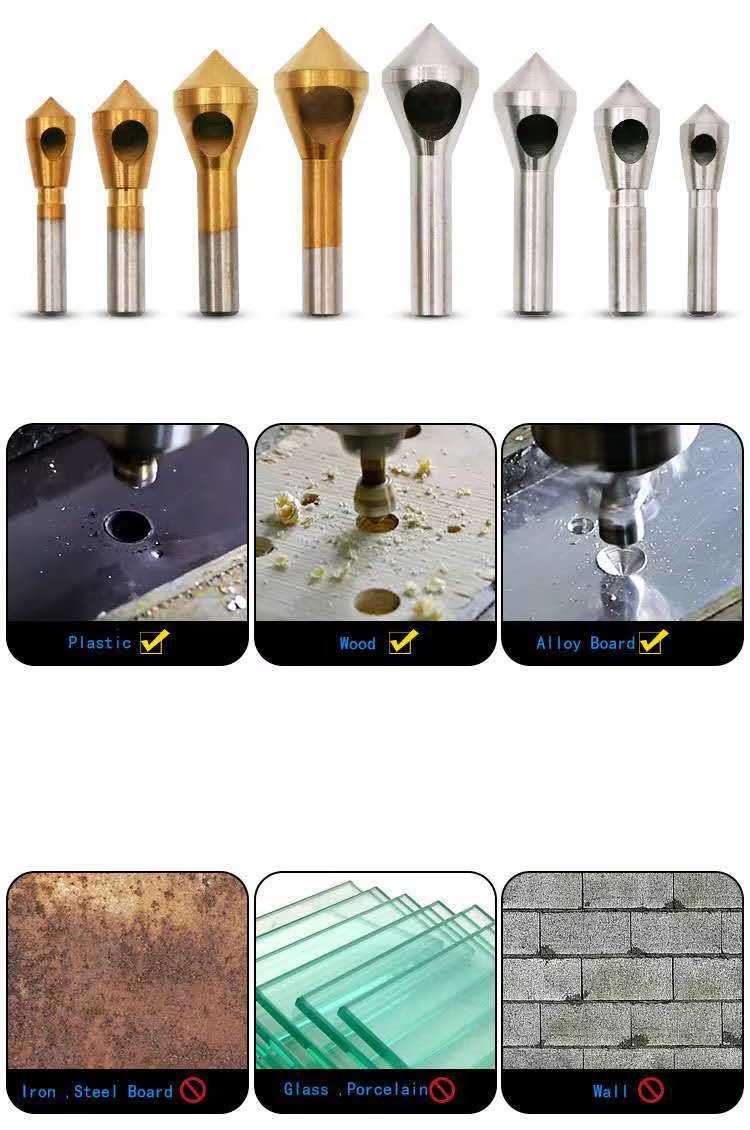

The HSS Chamfer Tool with a 90° chamfer angle is specifically designed for creating smooth, precise chamfers in various materials, including plastic, wood, and alloy boards. This tool is commonly used for deburring, countersinking, and drilling operations. Its titanium coating enhances performance by reducing friction and improving tool life, making it more durable than uncoated alternatives.

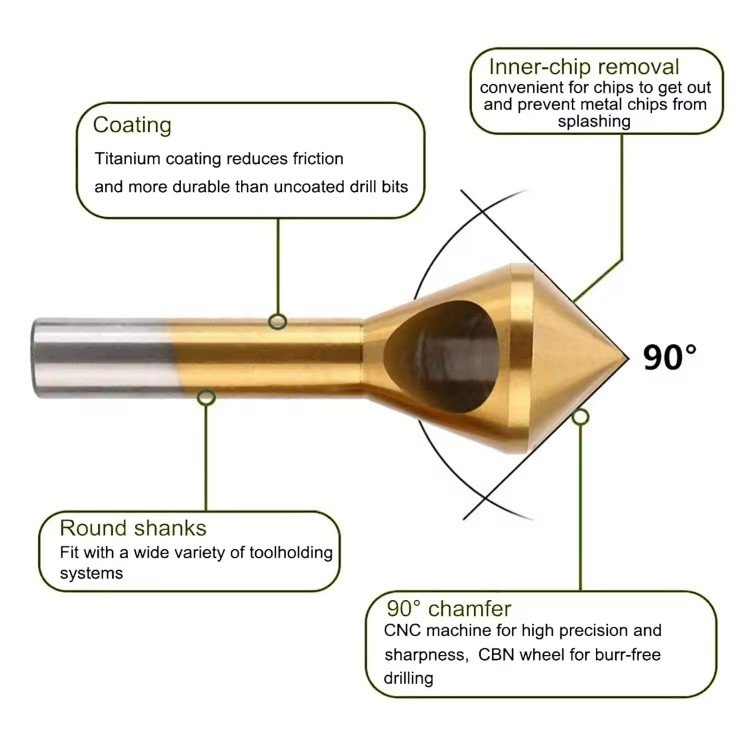

The 90° chamfer design is ideal for creating sharp, clean edges on holes, which is essential for many machining operations, such as assembly, fitting, and surface preparation. The chamfer tool allows for a smoother finish, which is critical in applications that require deburring and precise edge creation.

Efficient chip removal is a standout feature of this tool, ensuring that metal chips are effectively cleared during operation. This prevents chip buildup and minimizes the risk of splashing or clogging, which enhances safety and ensures a clean, precise hole. The tool’s design also accommodates various toolholding systems thanks to its round shank, offering versatility across different CNC machines.

This chamfer tool is equipped for high-precision machining, making it suitable for a range of industries, including electronics, automotive, and aerospace. The titanium coating ensures that the tool maintains its sharpness for extended use, even in tough materials, providing burr-free results after every cut.

Whether you are working on wood, plastic, or metal, this tool will deliver consistent, high-quality chamfering. Ideal for high-speed CNC applications, it is perfect for users seeking reliable, precise chamfering tools that provide excellent value and performance.

Key Features:

90° chamfer angle for precise edge creation and hole preparation

Titanium coating for reduced friction and extended tool life

Efficient chip removal design to ensure a clean, smooth finish

Round shank design for compatibility with various toolholding systems

Ideal for chamfering, deburring, and countersinking in CNC machines