Product English Description:

The 55° PEX series 4-flute end mills are engineered for high-performance cutting of tough materials such as cast iron, stainless steel, copper alloys, and carbon steel. Made from high-quality tungsten carbide, these end mills provide exceptional durability and wear resistance, ensuring superior cutting performance even under heavy-duty conditions.

With a 55° helix angle, these tools provide excellent cutting efficiency, ensuring smooth and efficient operations, especially in high-speed machining. The 4-flute design enhances stability, reduces vibrations, and improves chip removal, making them ideal for demanding milling operations that require precision and high material removal rates.

Coated with advanced ALTIN nano coating, the 55° PEX end mills offer enhanced heat resistance, wear resistance, and reduced friction. The coating also prevents material buildup, ensuring consistent performance and extending tool life, even during long machining sessions.

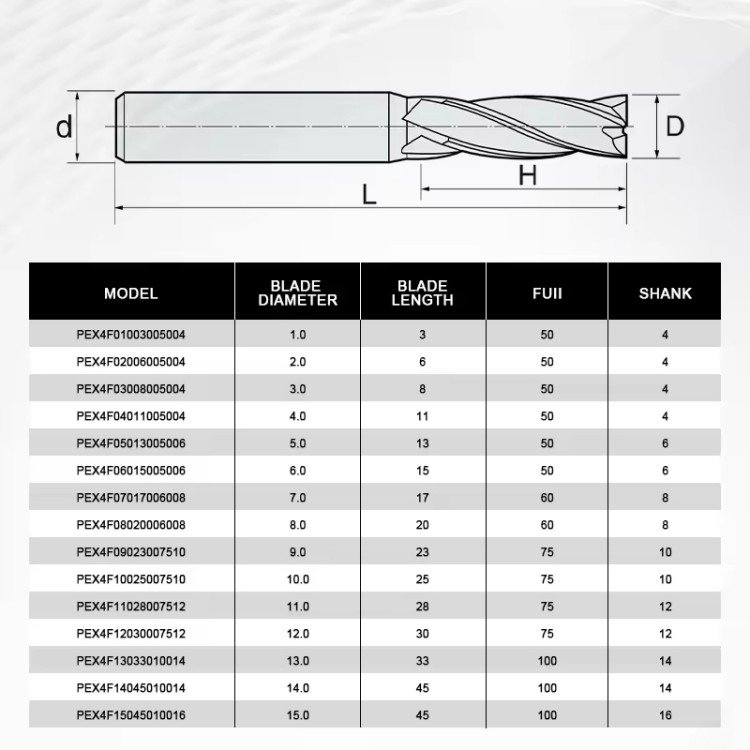

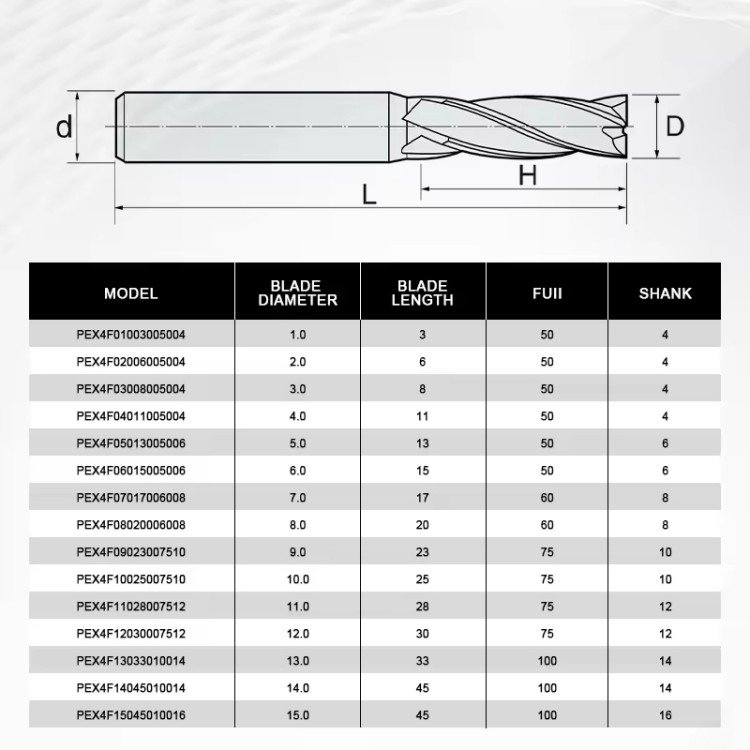

Available in a range of diameters, from 1.0mm to 15.0mm, and various blade lengths, these end mills are versatile for a wide variety of machining applications. They are particularly effective for contouring, slotting, and finishing tasks in challenging materials.

Key Features:

4-flute design for improved cutting stability and efficient chip removal

Made from high-quality tungsten carbide for long-lasting durability

55° helix angle for excellent cutting performance and smooth finishes

Advanced ALTIN nano coating for enhanced heat and wear resistance

Ideal for machining cast iron, stainless steel, copper alloys, and carbon steel

Available in diameters from 1.0mm to 15.0mm and blade lengths from 3mm to 45mm

Optimize your machining processes with the 55° PEX 4-flute end mills. Designed for high-speed, high-precision milling, these tools provide exceptional cutting performance and extended tool life, making them perfect for a range of industrial applications.