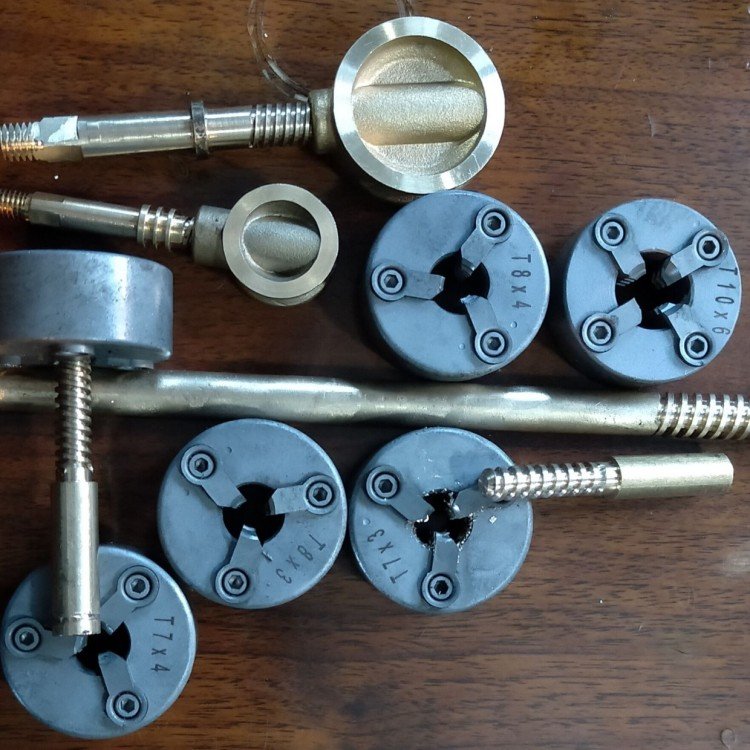

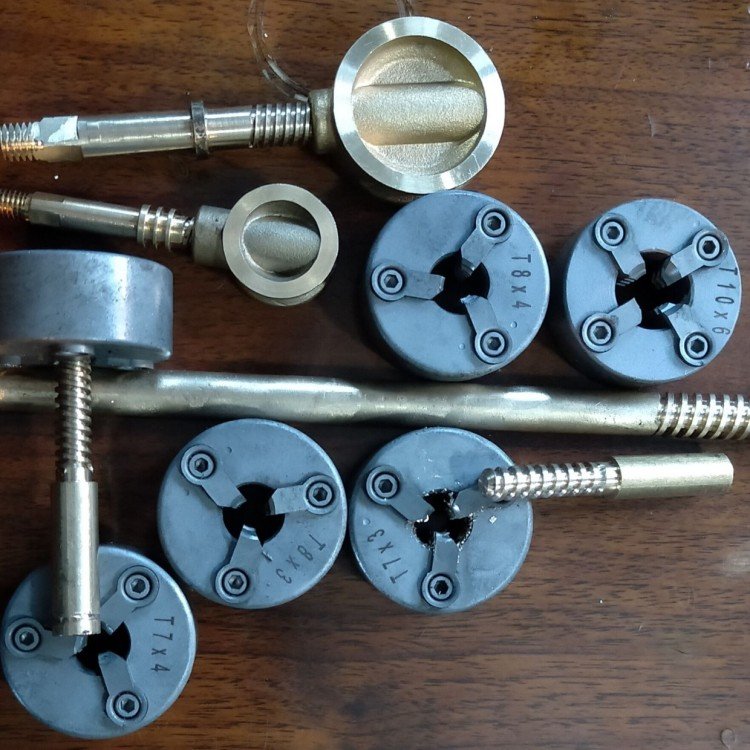

Our Tungsten Carbide Taps and Dies are designed for high-precision threading applications, offering superior durability and exceptional performance. Made from high-quality tungsten carbide, these threading tools are ideal for cutting precise threads in a variety of materials, including metals, alloys, and plastics. Whether you’re working with taper taps, bottoming taps, or threading dies, our tungsten carbide tools provide the sharpness and reliability required for high-demand industries such as automotive, aerospace, and manufacturing.

Key Features:

Premium Tungsten Carbide Construction: The Tungsten Carbide Taps and Dies offer outstanding wear resistance, hardness, and longevity. This makes them ideal for cutting through tough materials without losing sharpness.

High-Precision Threading: These taps and dies are engineered to produce clean, accurate threads every time, ensuring a perfect fit for fasteners, bolts, and threaded components.

Versatile Application: Suitable for cutting G1/2-14 threads, RC3/4-14, and a wide range of other sizes, these tools are perfect for a variety of threading jobs, including UNC, UNF, and metric threads.

Superior Performance: The tungsten carbide material is known for its high hardness and strength, allowing the tools to maintain their cutting edge for longer periods and providing consistent performance during extended use.

Wide Range of Sizes: Available in various sizes and thread types, including BSP, UNC, and custom designs, these tools are perfect for both professional machinists and DIY enthusiasts.

Specifications:

Material: Tungsten Carbide (WC)

Thread Types: BSP, UNC, UNF, Metric, and more

Sizes Available:

G1/2-14, RC3/4-14, G1/4-14, G1/2-14, and other custom sizes

Custom designs for unique threading needs

Thread Design: Precision threads for high-quality, reliable results

Durability: High wear and heat resistance for extended tool life

Applications:

The Tungsten Carbide Taps and Dies are ideal for:

Threading in automotive, aerospace, and mechanical engineering industries

Creating accurate threads for fasteners, bolts, and nuts

Precision tap and die threading for BSP, UNC, UNF, and metric threads

Threading tough materials such as steel, aluminum, and high-strength alloys