Product Description:

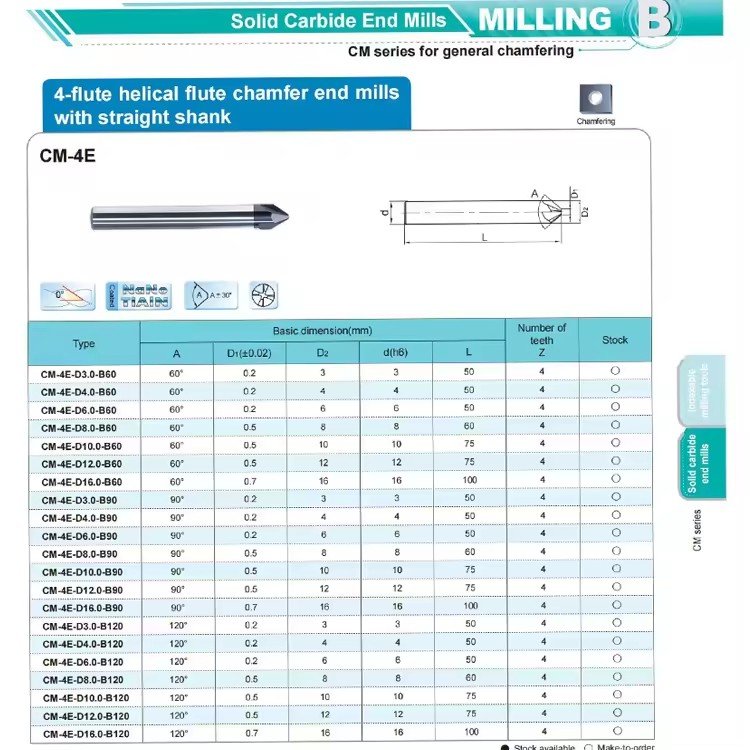

The CM-4E series offers high-performance 4-flute solid carbide chamfer end mills designed for precise chamfering applications. These tools are ideal for creating high-quality, sharp edges on materials like steel, aluminum, and other alloys. Featuring a straight shank design, these end mills are engineered to provide excellent rigidity, ensuring a smooth and accurate cutting process. The helical flute geometry allows for effective chip removal, improving efficiency during high-speed milling operations.

Built with solid carbide, the CM-4E series offers outstanding wear resistance and durability, making them suitable for both general and high-speed machining tasks. The chamfer angles range from 60° to 120°, providing versatility for different cutting requirements. These mills are specifically designed to ensure clean, precise chamfer cuts, helping to achieve superior surface finishes even on hard materials.

Key Features:

4-flute design for improved cutting efficiency and chip removal.

Helical flute geometry ensures smooth cutting and reduces vibrations.

Solid carbide construction offers exceptional durability and wear resistance.

Available in multiple chamfer angles (60°, 90°, 120°) for versatile applications.

Ideal for chamfering steel, aluminum, and alloy materials with precision.

Straight shank design for secure tool fitting and reliable performance.

The CM-4E chamfer end mills are ideal for industries that require high precision, such as aerospace, automotive, and mold making. Whether performing general chamfering or high-speed machining, these tools provide long tool life and excellent results, ensuring a smooth cutting process with minimal tool wear.

Perfect for achieving clean, uniform chamfers on complex parts, these end mills are engineered to handle both light and heavy-duty applications, offering reliability and precision for a variety of milling needs.